POLYJET PHOTOPOLYMERS

Vero

PolyJet Vero materials are rigid opaque photopolymers, widely used for visual models, engineering prototypes, product assemblies and RTV molding patterns. They can be blended with other photopolymers to vary hardness, flexibility, translucency or heat resistance.

See The Specs

Machine Availability: Objet30 Pro, Objet30 Prime, Eden260VS, Objet260 Connex1, Objet260 Connex3, Objet500 Connex1, Objet350/500 Connex3, Objet1000 Plus, J4100, Stratasys J735/J750, Stratasys J826 Prime / J835 / J850 Prime

Layer Height: 0.00055 in., 0.0006 in., 0.0011 in.

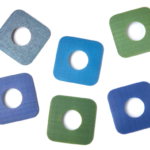

Color Options: VeroBlackPlus, VeroBlue, VeroCyan, VeroGray, VeroMagenta, VeroPureWhite, VeroYellow, VeroMagentaV, VeroYellowV, VeroCyanV, VeroClear

Support Materials: SUP705, SUP706

Tensile Strength: 50 – 65 MPa (7,250 – 9,450 psi)

Elongation at Break: 10 – 25%

Flexural Strength: 75 – 110 MPa (11,000 – 16,000 psi)

Shore Hardness (D): 83 – 86 (Scale D)

Request A Quote

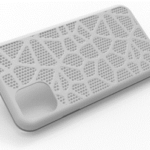

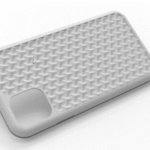

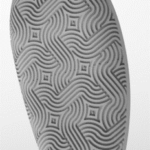

Consumer Goods Prototyping

An industrial design company sought the help of Shuvon Ghose, a member of Stratasys Software, Go-To-Market Team, to help produce a multi-material controller prototype.

Shuvon emphasized the importance of material choice by explaining that it, “makes a huge difference to the realism of your model.” He determined that VeroWhite for the body and rubber-like Agilus30 for the buttons would be the best choices for this prototype. Soon Shuvon experimented with adding color and quickly starting producing a multitude of designs. This technology makes it economically feasible to quickly create many different design iterations before pitching the final product.

This is only one case where Vero helped a company develop a product. There are unlimited possibilities with a material so versatile. To learn more about the 3D printing material options for your project, contact our team.

POLYJET PHOTOPOLYMERS

Vero

PolyJet Vero materials are rigid opaque photopolymers, widely used for visual models, engineering prototypes, product assemblies and RTV molding patterns. They can be blended with other photopolymers to vary hardness, flexibility, translucency or heat resistance.

See The Specs

Machine Availability: Objet30 Pro, Objet30 Prime, Eden260VS, Objet260 Connex1, Objet260 Connex3, Objet500 Connex1, Objet350/500 Connex3, Objet1000 Plus, J4100, Stratasys J735/J750, Stratasys J826 Prime / J835 / J850 Prime

Layer Height: 0.00055 in., 0.0006 in., 0.0011 in.

Color Options: VeroBlackPlus, VeroBlue, VeroCyan, VeroGray, VeroMagenta, VeroPureWhite, VeroYellow, VeroMagentaV, VeroYellowV, VeroCyanV, VeroClear

Support Materials: SUP705, SUP706

Tensile Strength: 50 – 65 MPa (7,250 – 9,450 psi)

Elongation at Break: 10 – 25%

Flexural Strength: 75 – 110 MPa (11,000 – 16,000 psi)

Shore Hardness (D): 83 – 86 (Scale D)

Request A Quote

Consumer Goods Prototyping

An industrial design company sought the help of Shuvon Ghose, a member of Stratasys Software, Go-To-Market Team, to help produce a multi-material controller prototype.

Shuvon emphasized the importance of material choice by explaining that it, “makes a huge difference to the realism of your model.” He determined that VeroWhite for the body and rubber-like Agilus30 for the buttons would be the best choices for this prototype. Soon Shuvon experimented with adding color and quickly starting producing a multitude of designs. This technology makes it economically feasible to quickly create many different design iterations before pitching the final product.

This is only one case where Vero helped a company develop a product. There are unlimited possibilities with a material so versatile. To learn more about the 3D printing material options for your project, contact our team.

POLYJET PHOTOPOLYMERS

Vero

PolyJet Vero materials are rigid opaque photopolymers, widely used for visual models, engineering prototypes, product assemblies and RTV molding patterns. They can be blended with other photopolymers to vary hardness, flexibility, translucency or heat resistance.

See The Specs

Machine Availability: Objet30 Pro, Objet30 Prime, Eden260VS, Objet260 Connex1, Objet260 Connex3, Objet500 Connex1, Objet350/500 Connex3, Objet1000 Plus, J4100, Stratasys J735/J750, Stratasys J826 Prime / J835 / J850 Prime

Layer Height: 0.00055 in., 0.0006 in., 0.0011 in.

Color Options: VeroBlackPlus, VeroBlue, VeroCyan, VeroGray, VeroMagenta, VeroPureWhite, VeroYellow, VeroMagentaV, VeroYellowV, VeroCyanV, VeroClear

Support Materials: SUP705, SUP706

Tensile Strength: 50 – 65 MPa (7,250 – 9,450 psi)

Elongation at Break: 10 – 25%

Flexural Strength: 75 – 110 MPa (11,000 – 16,000 psi)

Shore Hardness (D): 83 – 86 (Scale D)

Request A Quote

Consumer Goods Prototyping

An industrial design company sought the help of Shuvon Ghose, a member of Stratasys Software, Go-To-Market Team, to help produce a multi-material controller prototype.

Shuvon emphasized the importance of material choice by explaining that it, “makes a huge difference to the realism of your model.” He determined that VeroWhite for the body and rubber-like Agilus30 for the buttons would be the best choices for this prototype. Soon Shuvon experimented with adding color and quickly starting producing a multitude of designs. This technology makes it economically feasible to quickly create many different design iterations before pitching the final product.

This is only one case where Vero helped a company develop a product. There are unlimited possibilities with a material so versatile. To learn more about the 3D printing material options for your project, contact our team.