DLP 3D Printing

STRONG, END-USE PARTS

DLP is a manufacturing-grade 3D printing technology for the mass-production of end-use parts.

Why DLP?

With a wide range of production-grade materials, Porcupine has the right solution for any application.

With quick turnaround times and high throughput, you’ll be able to avoid expensive tooling costs.

The strength of DLP’s models allows them to be used as machined quality parts in an array of industries.

DLP and Purple Porcupine enable mass production of end-use parts in a diverse range of high-performance materials. You can receive industry-leading accuracy, consistency, detail, and mechanical properties. Expand production without delays, for faster launch times and flexibility with the technology’s high throughput combined with best-in-class repeatability. To learn more about how you can leverage Purple Porcupine and DLP technology, contact us today!

Request A Quote

The Process

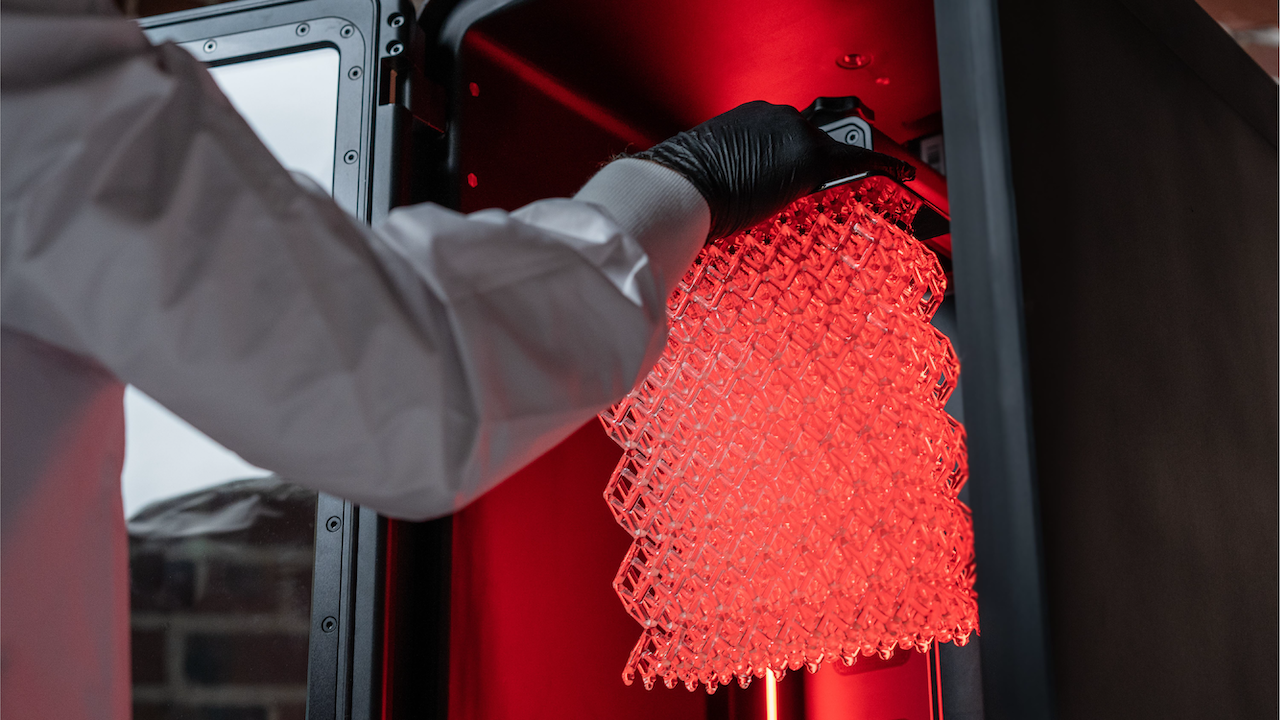

Pre-Processing: The 3D CAD model of a part or component is oriented, sliced, and positioned using special control software. This software translates the 3D data into two dimensional layers, corresponding to the part geometry, while also adding any support structures.

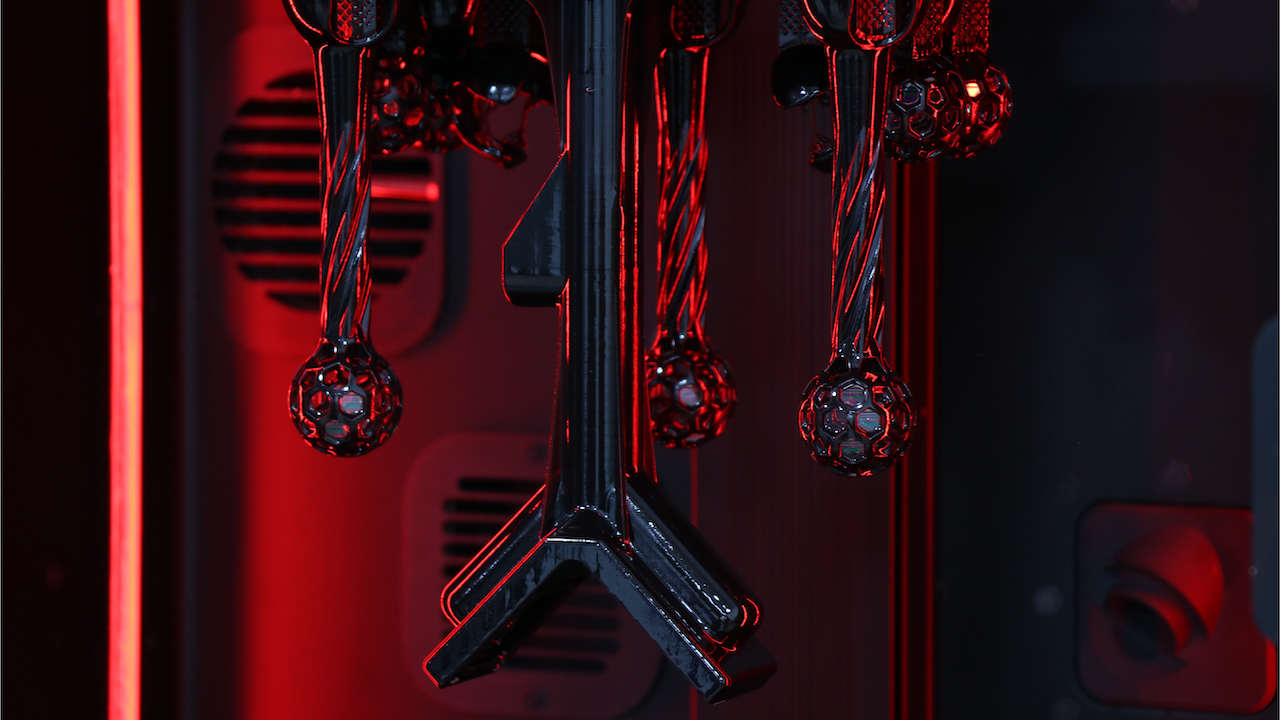

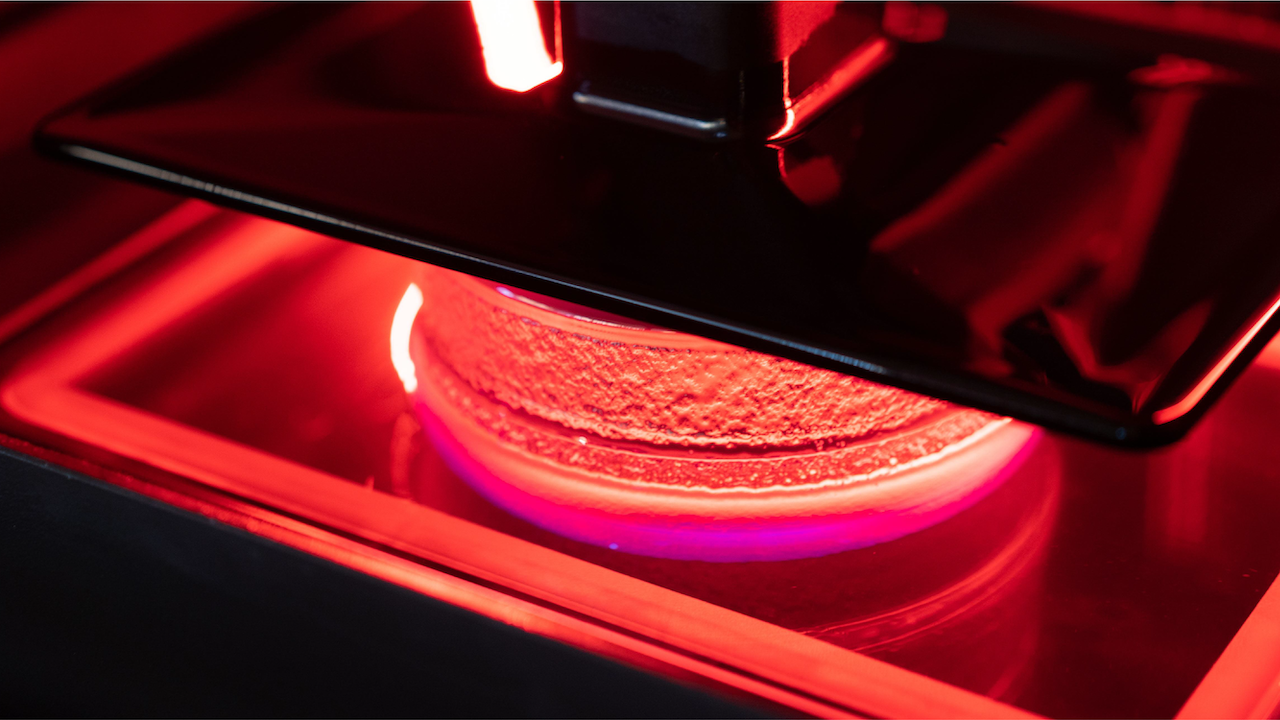

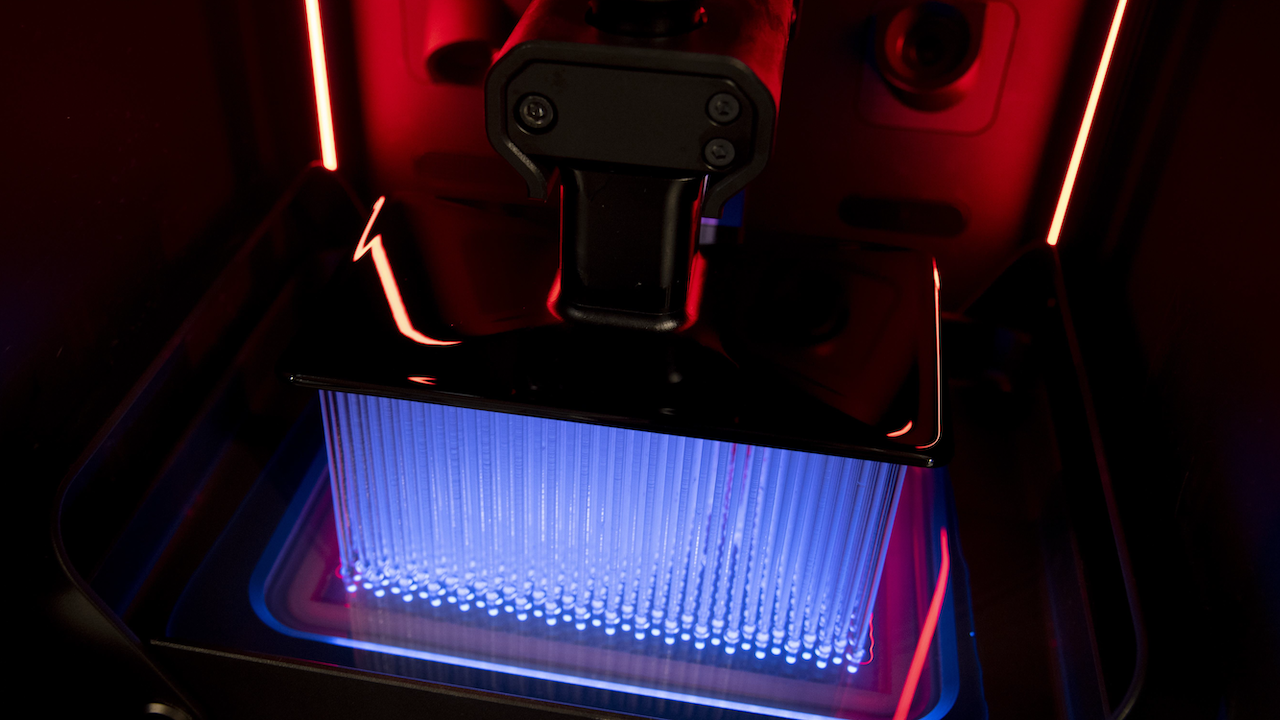

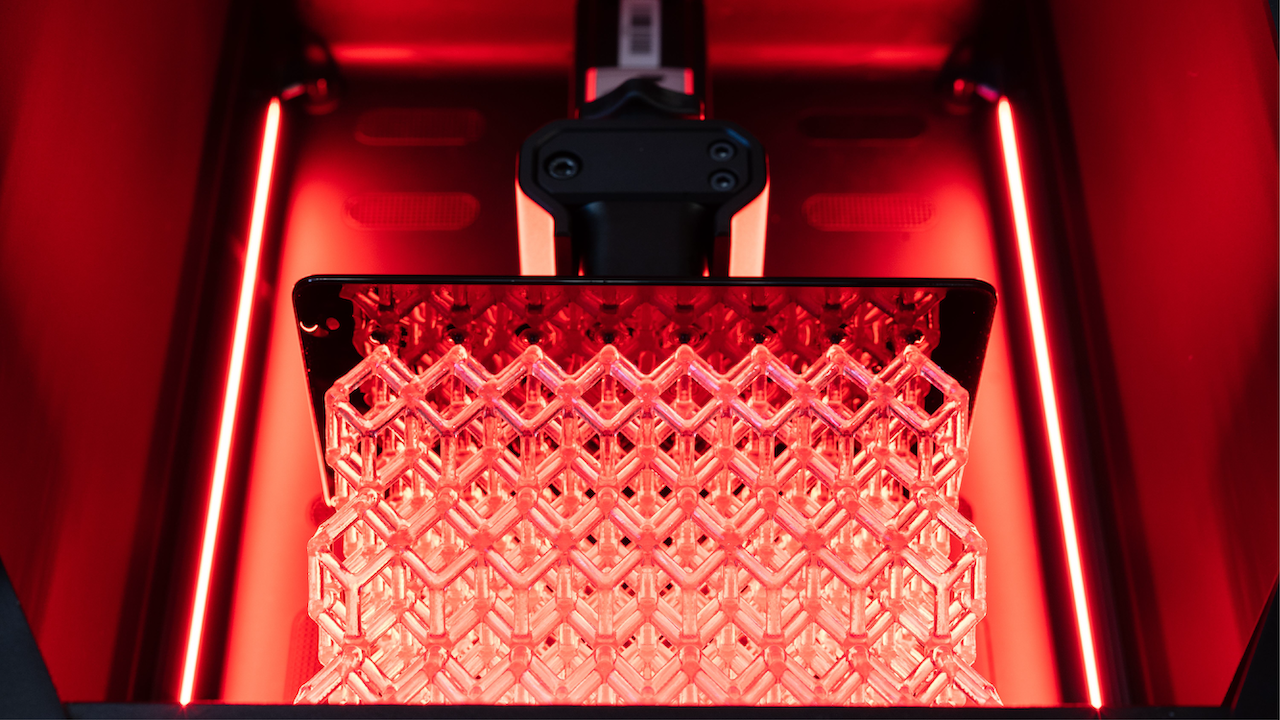

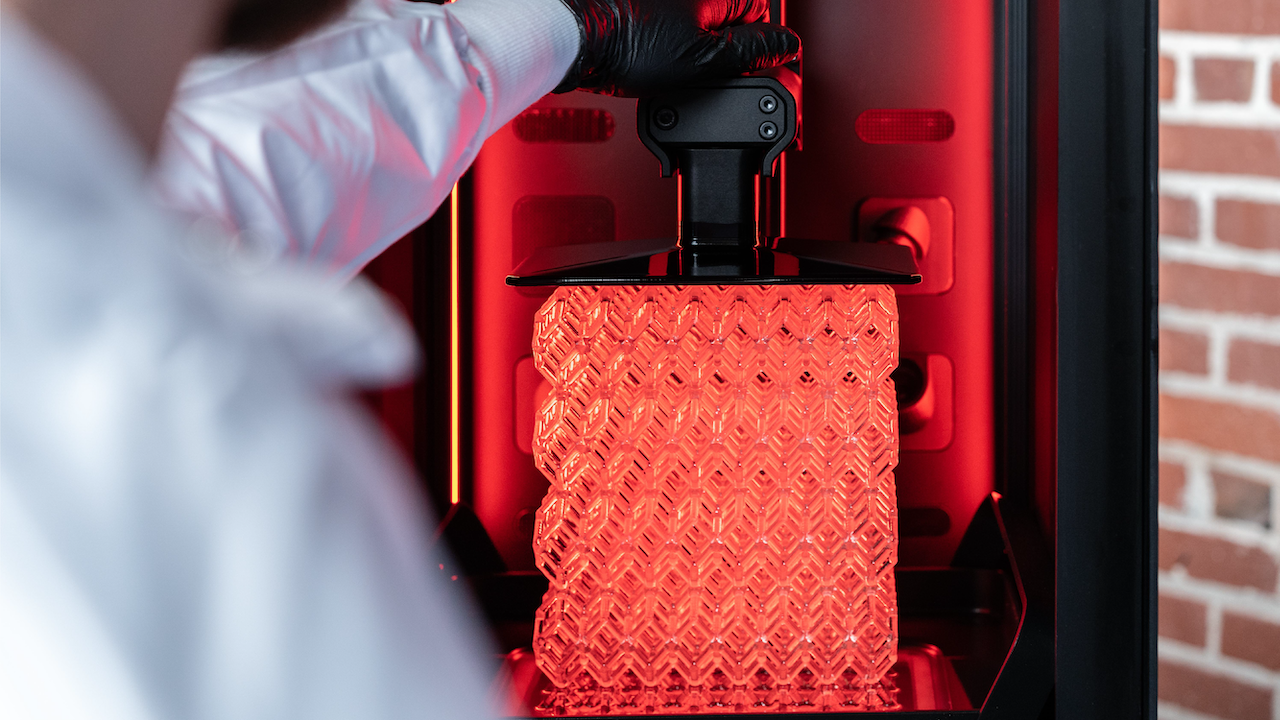

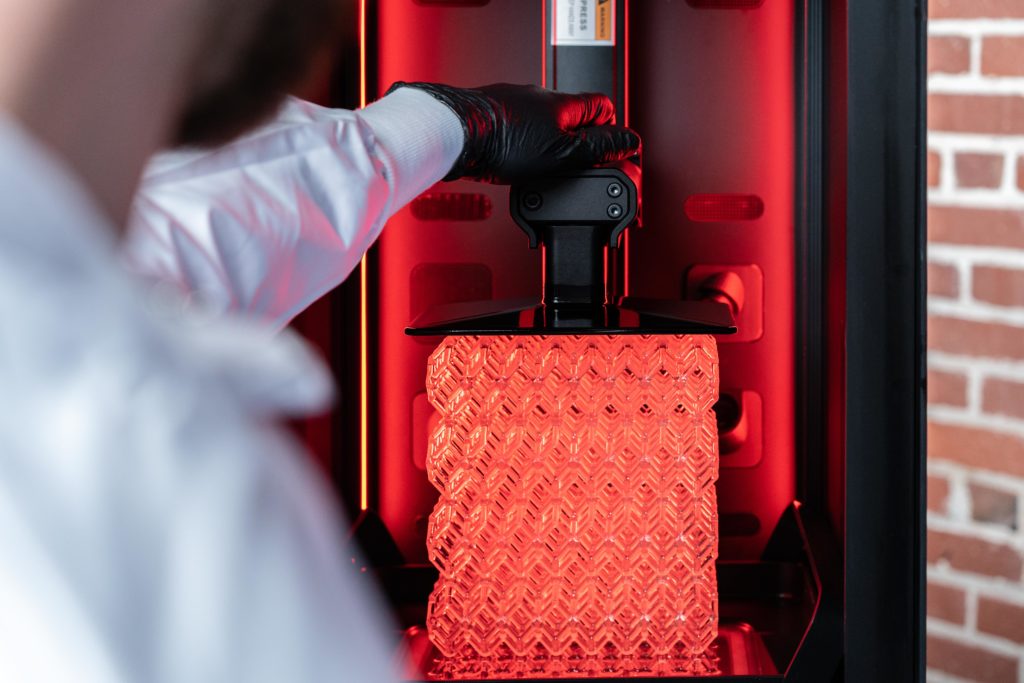

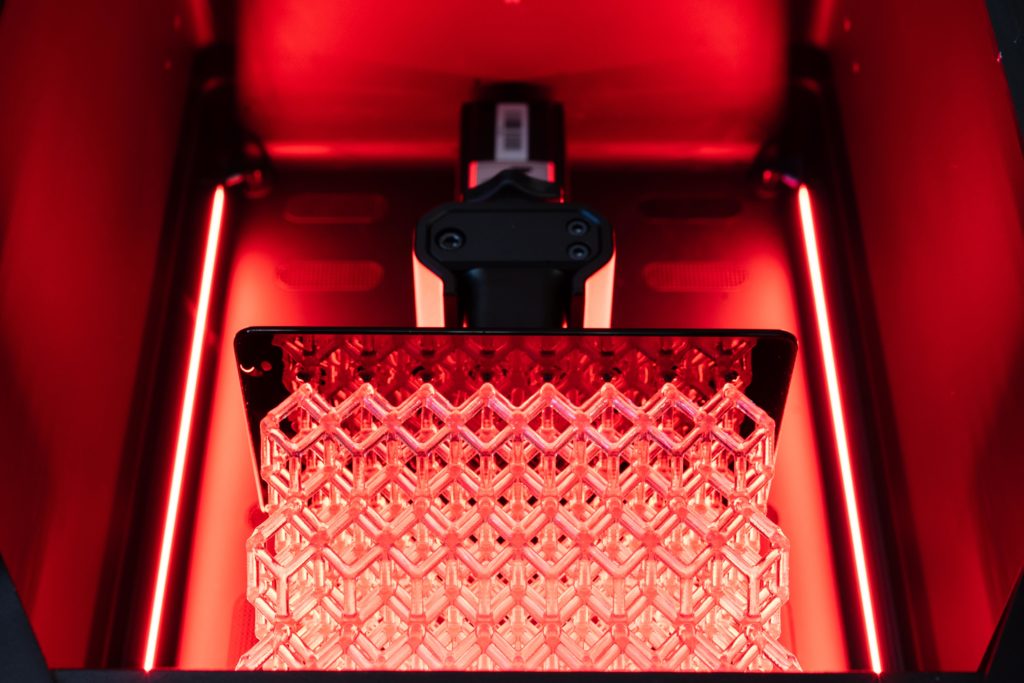

Production: The DLP process works by using a projector to flash an image on the resin curing that layer. The process is repeated until the model is complete.

Post-Processing: Once taken off the build platform, the final 3D printed part requires the manual removal of supporting structures. DLP parts may also require an Isopropyl alcohol bath and a secondary UV light curing.

At Purple Porcupine, you can depend on our 3D printing & rapid prototyping service to be exceptional, and our 3D printed models to hold tight tolerances with premium finishes. We use only the best of rapid prototyping technologies that will provide optimal solutions to change the way you design and create products.

ITAR Registered · 949.474.7222 · partsfast@purpleporcupine.com · Start Your Project Today