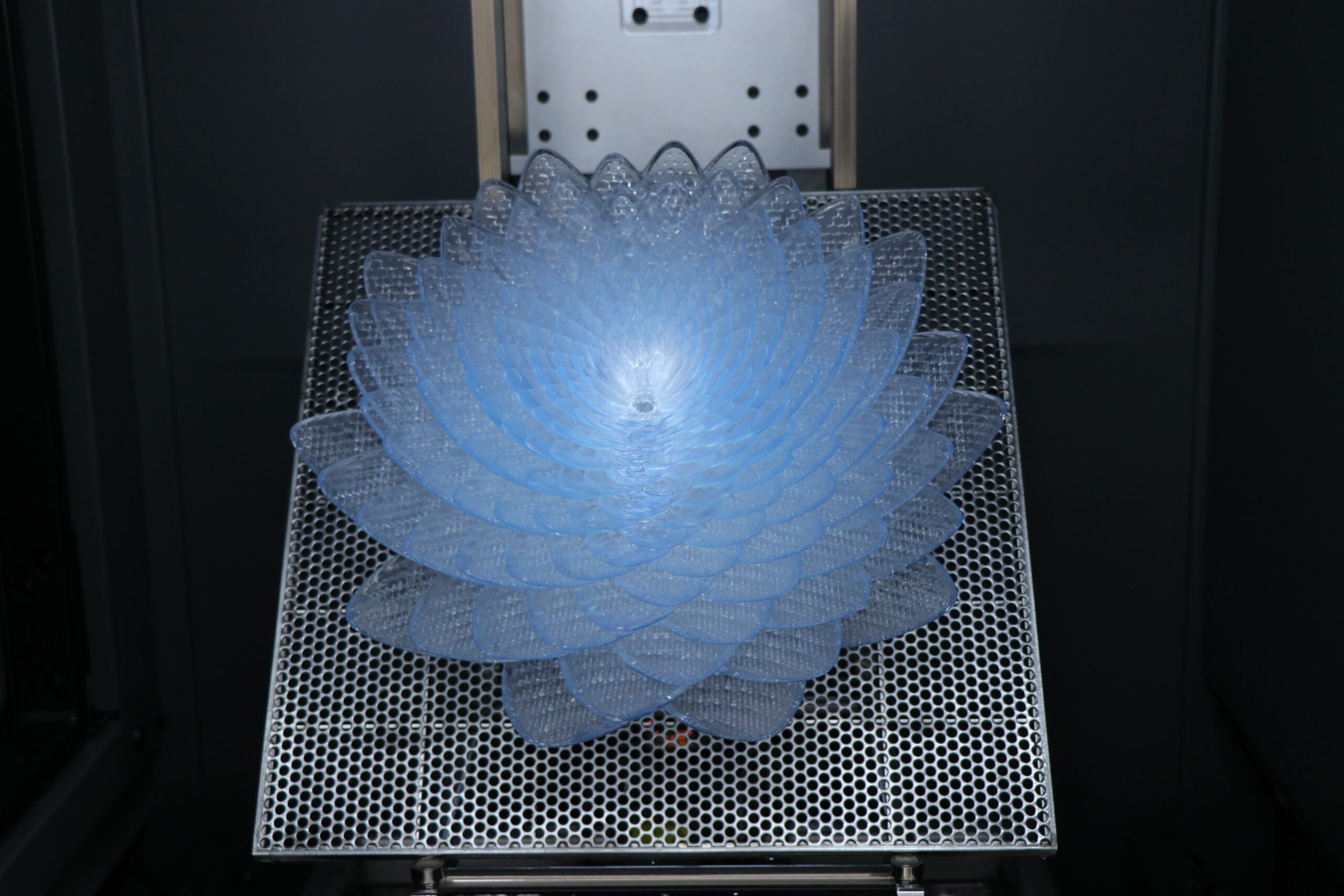

SLA 3D Printing

Speed & Precision

3D print detailed parts with tight tolerance requirements and incredibly smooth surface finishes with our Stereolithography (SLA) 3D printing services.

Why SLA?

Create small or large parts with smooth surface finishes.

Avoid expensive tooling costs, by producing small to medium production runs.

Build 3D models with a thick outer shell and a honeycomb interior, perfect for investment casting parts. Our team can 3D print your part fast, allowing for a quicker production timeline.

With a wide range of materials available, our team will help you find the perfect solution for your application.

Most often used to create investment casting patterns, SLA also creates extremely accurate parts, with smooth finishes and strict tolerance requirements. Other design applications include: small to large prototypes, large models for the automotive or entertainment industry, and master patterns for low-temperature molds. To learn more about how you can leverage Stereolithography, contact us today!

Request A Quote

The Process

Pre-Processing: The 3D CAD model of a part or component is oriented, sliced, and positioned using special control software. This software translates the 3D data into two dimensional layers, corresponding to the part geometry, while also adding any support structures.

Production: The SLA process uses UV lasers to trace and solidify a single layer of photopolymer in a specific geometry. The process is repeated until the model is complete.

Post-Processing: Once taken off the build platform, the final 3D printed part requires the manual removal of supporting structures. Some SLA parts may also require an Isopropyl alcohol bath and a secondary UV light curing.

How It Works

Contact Our Team

Reach out to our team through the above form or upload your 3D part file through our secure online upload system.

Finalize Your Design

Whether you’re using our CAD design engineering services or have a completed 3D design, our team will make sure your part will print error-free.

Print Your Part

With an average lead time of 2.6 days, our team will print, clean, and ship your part quickly and effectively, expediting your time-to-market.

At Purple Porcupine, you can depend on our 3D printing & rapid prototyping service to be exceptional, and our 3D printed models to hold tight tolerances with premium finishes. We use only the best of rapid prototyping technologies that will provide optimal solutions to change the way you design and create products.

ITAR Registered · 949.474.7222 · partsfast@purpleporcupine.com · Start Your Project Today