PBF Materials

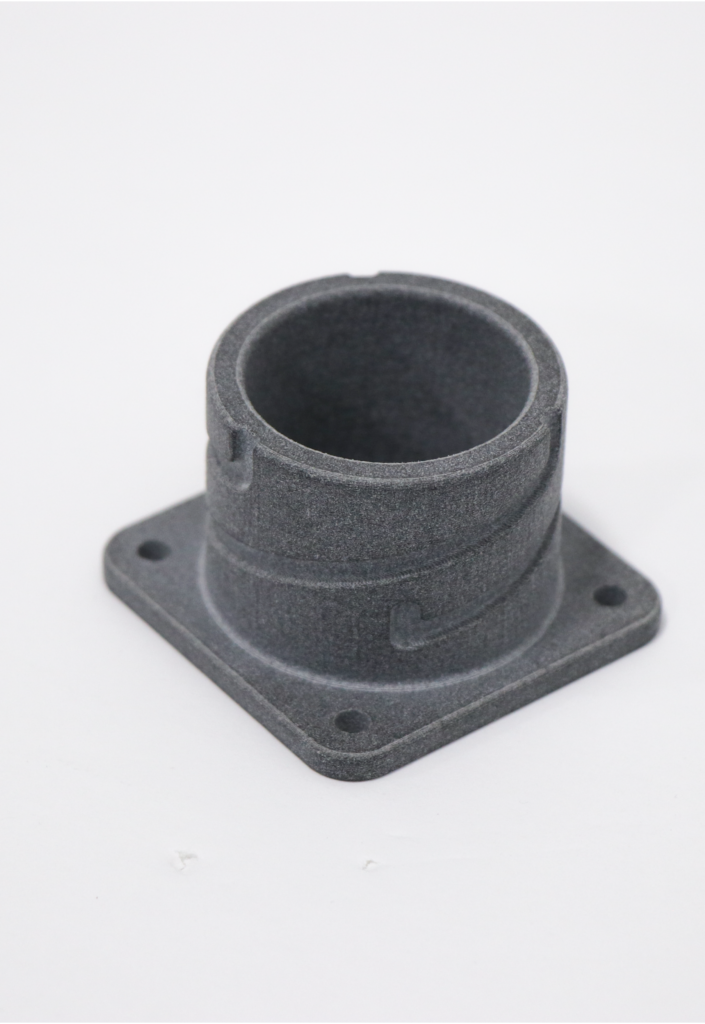

POWDER BED FUSION PRODUCTION PARTS

Create end-use functional parts in production quantities. 3D printing locally with Purple Porcupine will help you meet your demand, while saving the time normally associated with international outsourcing.

Production-Grade Parts For High-Volume Demand

Create production-grade plastic parts for high-volume demands – driving new areas of business growth. The materials deliver strong, functional parts; impact resistant parts; and smooth, end-use parts.

Explore the Materials

High Yield PA11

High-impact resistant material that maintains high part consistency for high-volume production of end-use parts.

Tensile Strength (XZ,YX): 51 MPa

Flexural Strength (XZ,YX): 35 MPa

Elongation at Break (XZ,YX): 30%

HDT @ 0.45 MPa: 185°C

PA12

Strong and impact-resistant general-use plastic, ideal for a broad range of applications.

Tensile Strength (XZ,YX): 47 MPa

Flexural Strength (XZ,YX): 40 MPa

Elongation at Break (XZ,YX): 11%

HDT @ 0.45 MPa: 173°C

PA12 GB

A nylon plastic infused with 40% glass beads, improving part stiffness and dimensional accuracy.

Tensile Strength (ZX,XY): 30 MPa

Flexural Strength (ZX,XY): 65 MPa

Elongation at Break (ZX,XY): 10%

HDT @ 0.45 MPa: 175°C

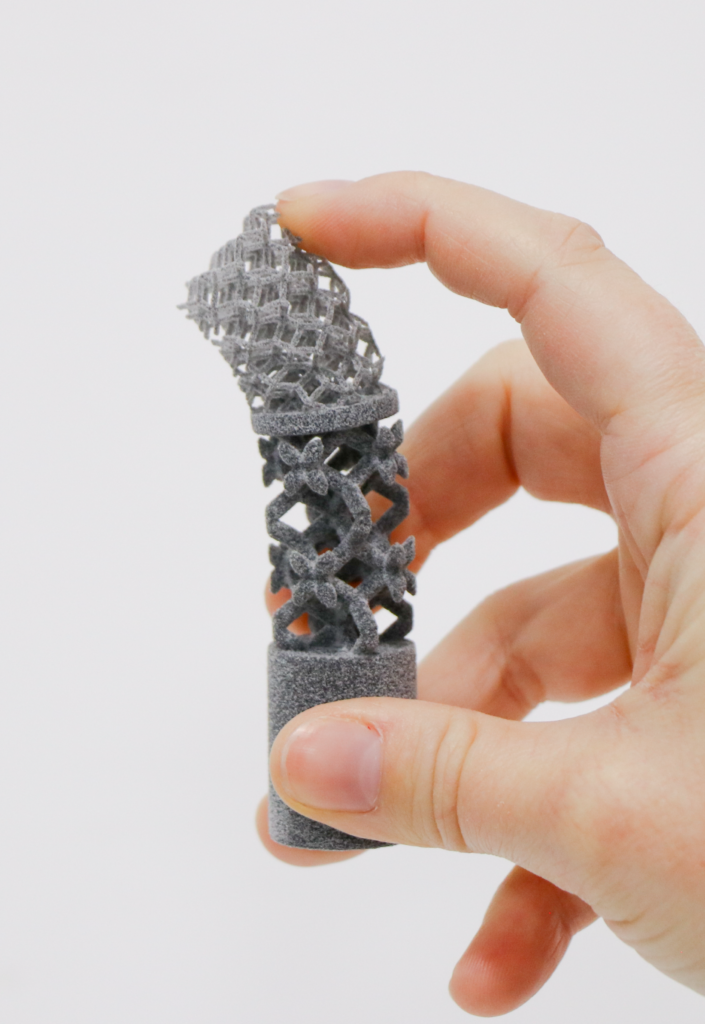

TPU

High-performing thermoplastic polyurethane material that creates rubber-like, tough, and impact resistant parts.

Tensile Strength (XY): 9 MPa

Flexural Modulus (XY): 75 MPa

Elongation at Break: 220%

Hardness Shore A: 88