3D Printing Services

MJF 3D Printing

REPEATABLE & COST-EFFECTIVE

Create dimensionally stable, repeatable parts with Purple Porcupine’s Multi Jet Fusion (MJF) 3D printing services.

Why MJF?

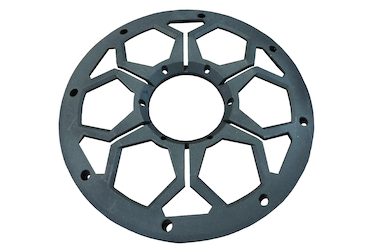

MJF technology provides repeatability and dimensional stability.

The method allows us to print functional, geometrically complex parts, with a layer thickness of 0.003 inches (or 0.08 mm).

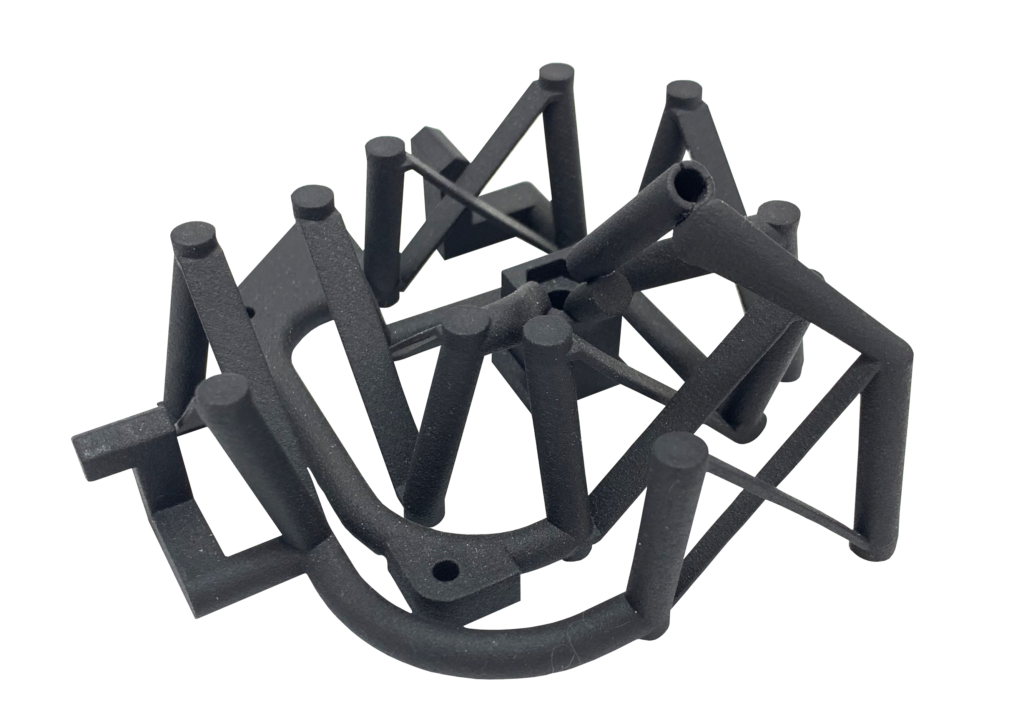

MJF is ideal for designs with complex geometries, including parts with internal cavities.

This cost-effective method of 3D printing is perfect for quantities greater than 30 pieces.

Request A Quote

Materials

PA 12 is strong thermoplastic with excellent chemical resistance and low moisture absorption. PA 12 is ideal for complex assemblies, enclosures, lattice structures, and connectors.

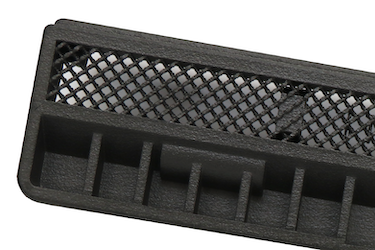

PA 12 GB, also known as PA 12 GF, is a dimensionally stable thermoplastic that is 40% filled with glass beads, allowing it to produce stiff, functional parts. PA 12 GB is ideal for functional parts, like jigs, fixtures, housings, and enclosures.

Applications

From batch production for testing and validation to end-use parts, MJF 3D printing applications are nearly endless. Some of the common design applications include: connectors, brackets, covers, thin-wall ductwork, non-cosmetic housings, grommets, wiring clips, and guides. MJF is ideal for designs with complex geometries, including parts with internal cavities.

How It Works

Contact Our Team

Reach out to our team through the above form or upload your 3D part file through our secure online upload system.

Finalize Your Design

Whether you’re using our CAD design engineering services or have a completed 3D design, our team will make sure your part will print error-free.

Print Your Part

With an average lead time of 2.6 days, our team will print, clean, and ship your part quickly and effectively, expediting your time-to-market.

The Process

Multi Jet Fusion is a powder-based technology that uses an inkjet array to selectively apply fusing agents across a layer of nylon powder. The nylon powder selection is fused by heat into a solid layer.

After a layer is created, powder is distributed on top of the bed again. The process repeats until the part is complete. To learn more, contact our team today!

At Purple Porcupine, you can depend on our 3D printing & rapid prototyping service to be exceptional, and our 3D printed models to hold tight tolerances with premium finishes. We use only the best of rapid prototyping technologies that will provide optimal solutions to change the way you design and create products.

ITAR Registered · 949.474.7222 · partsfast@purpleporcupine.com · Start Your Project Today

Rapid Prototyping. Today.

No matter what industry you come from, rapid prototyping is changing the way business is done. Through highly accurate, cost-effective and time-efficient processes, 3D rapid prototypes can be created in mere days.