Realize more opportunities with 3D printing

Realize more opportunities with 3D printing

Commercial manufacturers need the flexibility to make great products in small, medium or large volumes. Digital manufacturing solutions are often the difference between turning down potential business and cost-effectively serving a niche need.

Check out the custom 3D printed microphone that U2 used on tour; large-vehicle HVAC system prototypes; and a clever tooling hack for custom Xerox printers.

Throughout its history, efficiency and innovation have been core drivers of Ioxus Inc.’s business. Ioxus develops, manufactures and distributes ultracapacitor technologies for a wide range of energy storage markets. Its innovative products extend the charge time and reduce the use of batteries for electronics, hybrid vehicles, wind farms, and other green technologies. Ioxus’ parent company, Custom Electronics, Inc. (CEI) has been manufacturing high voltage capacitors since 1964.

Throughout its history, efficiency and innovation have been core drivers of Ioxus Inc.’s business. Ioxus develops, manufactures and distributes ultracapacitor technologies for a wide range of energy storage markets. Its innovative products extend the charge time and reduce the use of batteries for electronics, hybrid vehicles, wind farms, and other green technologies. Ioxus’ parent company, Custom Electronics, Inc. (CEI) has been manufacturing high voltage capacitors since 1964.

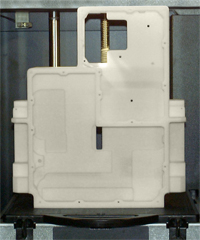

CEI began to investigate 3D printing as a way to cut the cost and turnaround times for tools and fixtures they were producing through outside machine shops. They were also looking for a way to produce housings and molds for prototypes.

Dimension Recharges Design and Manufacturing

After researching a variety of options, CEI purchased a Dimension 3D Printer. Designed to create precise three-dimensional models, Dimension 3D printers convert CAD files into durable models, right from a workstation or network.

The impact of the Dimension 3D Printer on the two businesses has been dramatic. Ioxus estimates that their small shop has saved over $100,000 in machining and prototyping since we purchased the printer three years ago.

“Parts that used to take us six weeks at the machine shop and cost $500 to $1500 per item, I now turn around in hours for less than $20,” said Ioxus COO Chad Hall (formerly Engineering Manager of CEI). “Recently, we built a high voltage capacitor housing in less than two days with the Dimension 3D Printer at a cost of just $250. That same piece would have taken fourteen weeks to machine at a cost of $12,500.”

CEI has used the Dimension 3D Printer extensively to create nesting jigs and fixtures for assembly and soldering processes. “We thread on holding mechanisms and glue sheets of metal where needed to prevent damage during soldering,” said Hall.

In addition, Ioxus has used the Dimension 3D Printer for marketing to potential clients. “We’ve printed models of our revolutionary design ideas in the Dimension 3D Printer and used them to attract customers and investors,” said Hall. “It’s an incredibly powerful way to communicate the possibilities in an industry that requires a high degree of specialization.”